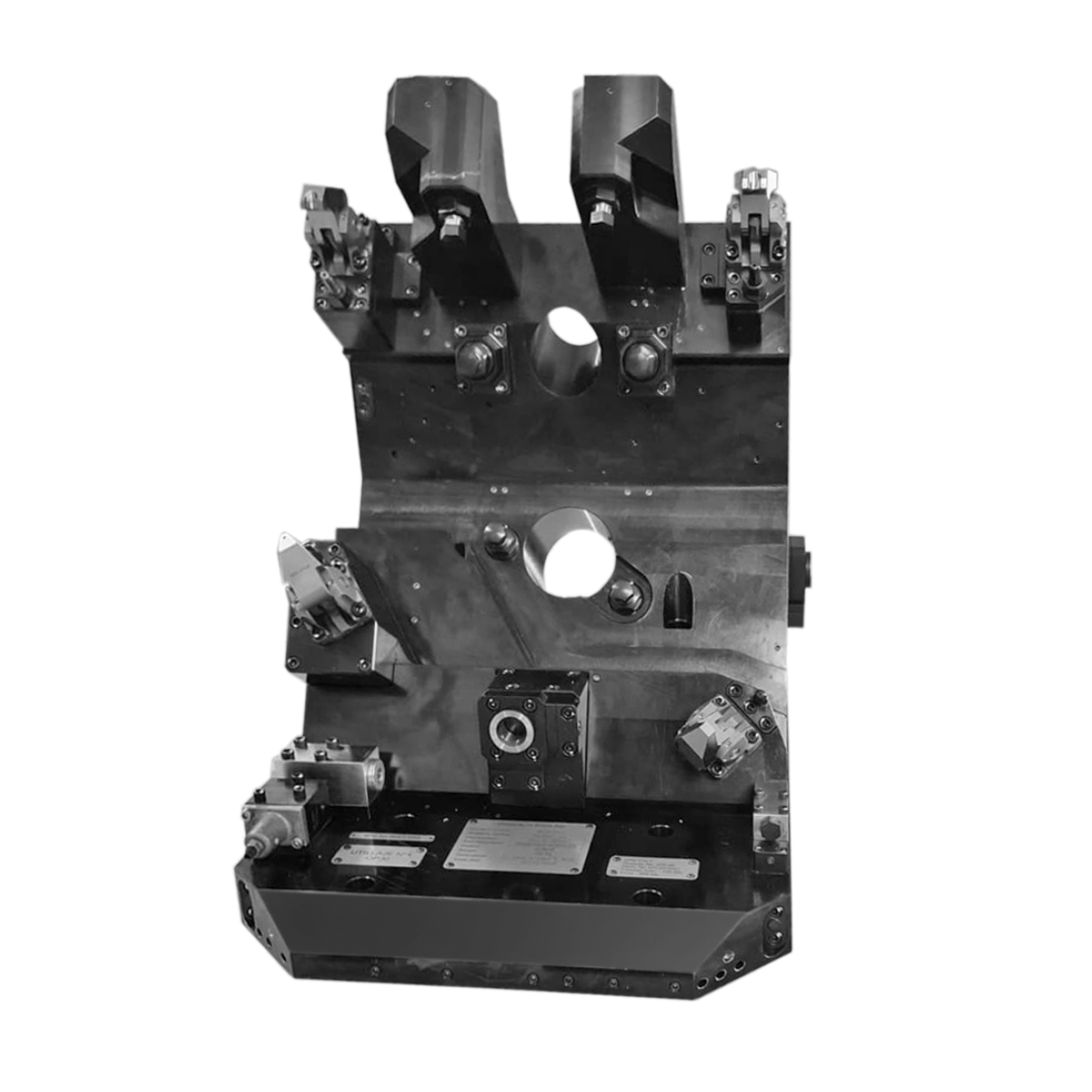

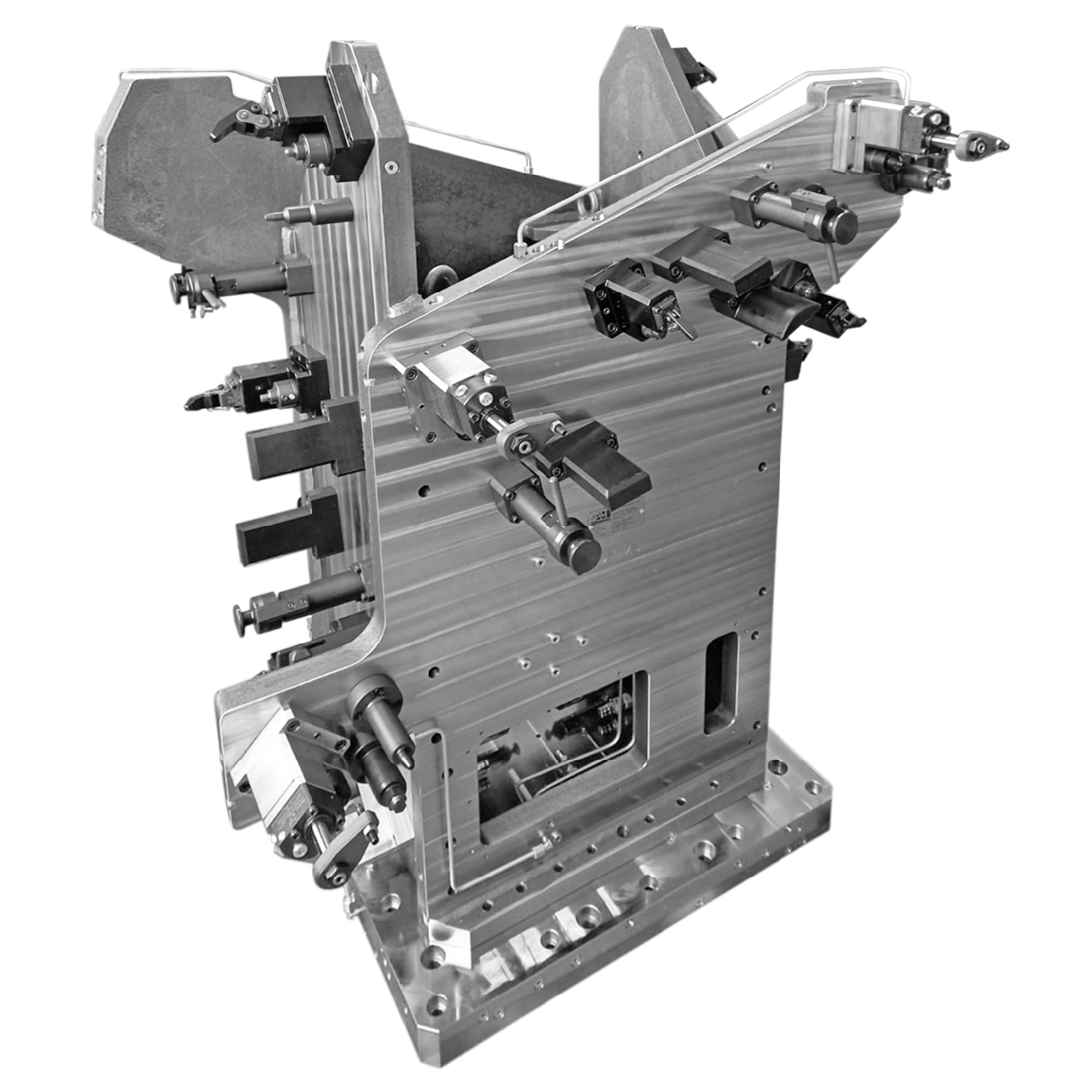

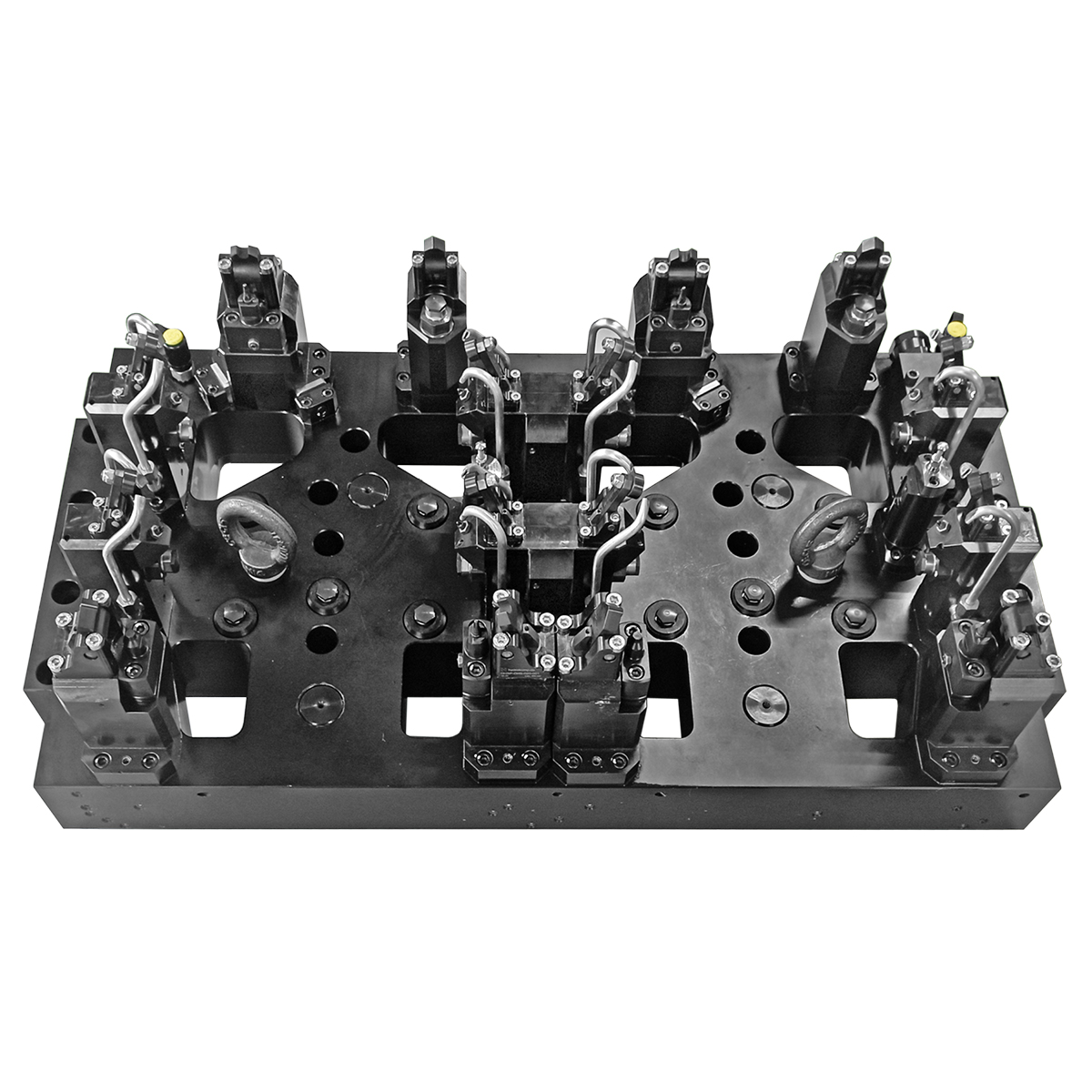

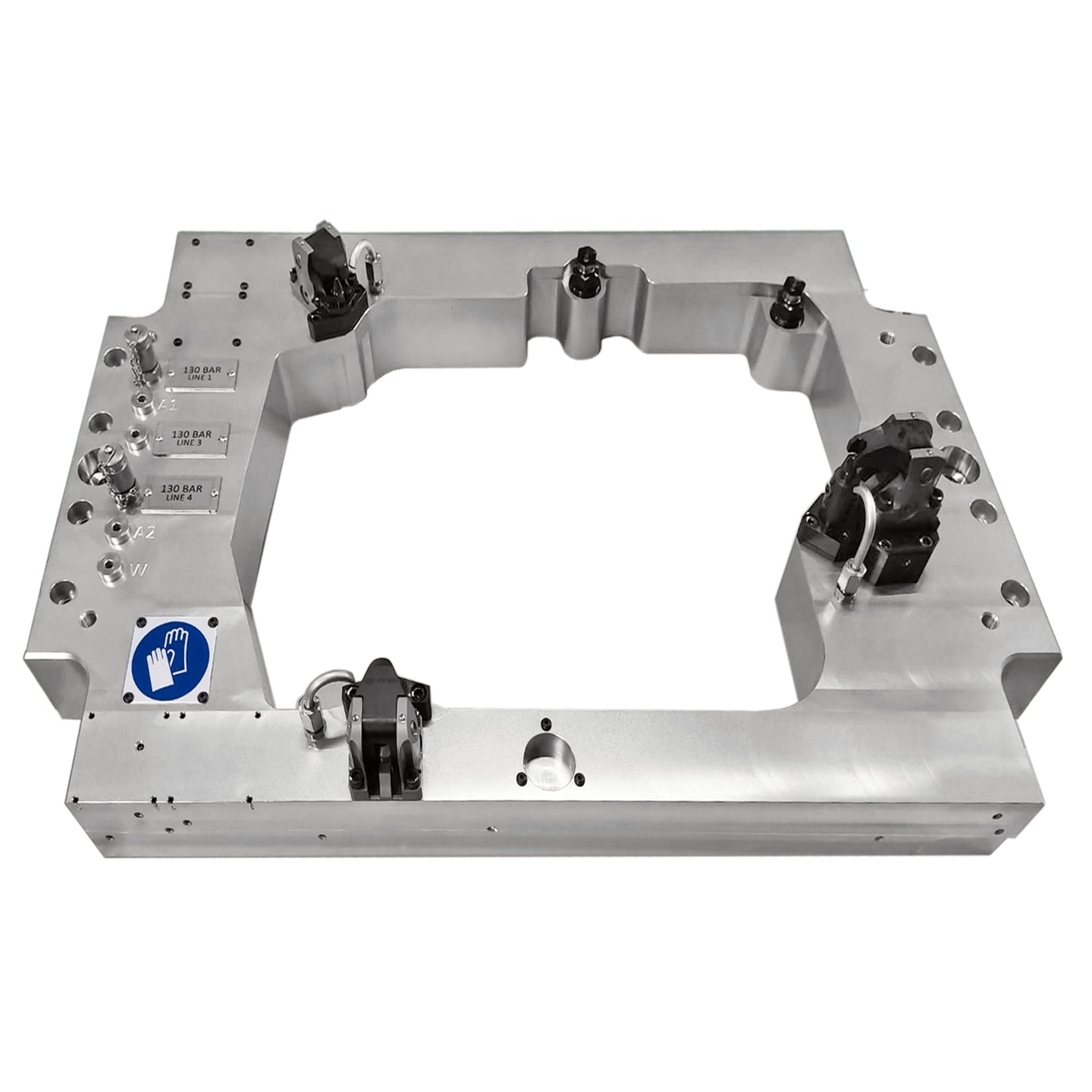

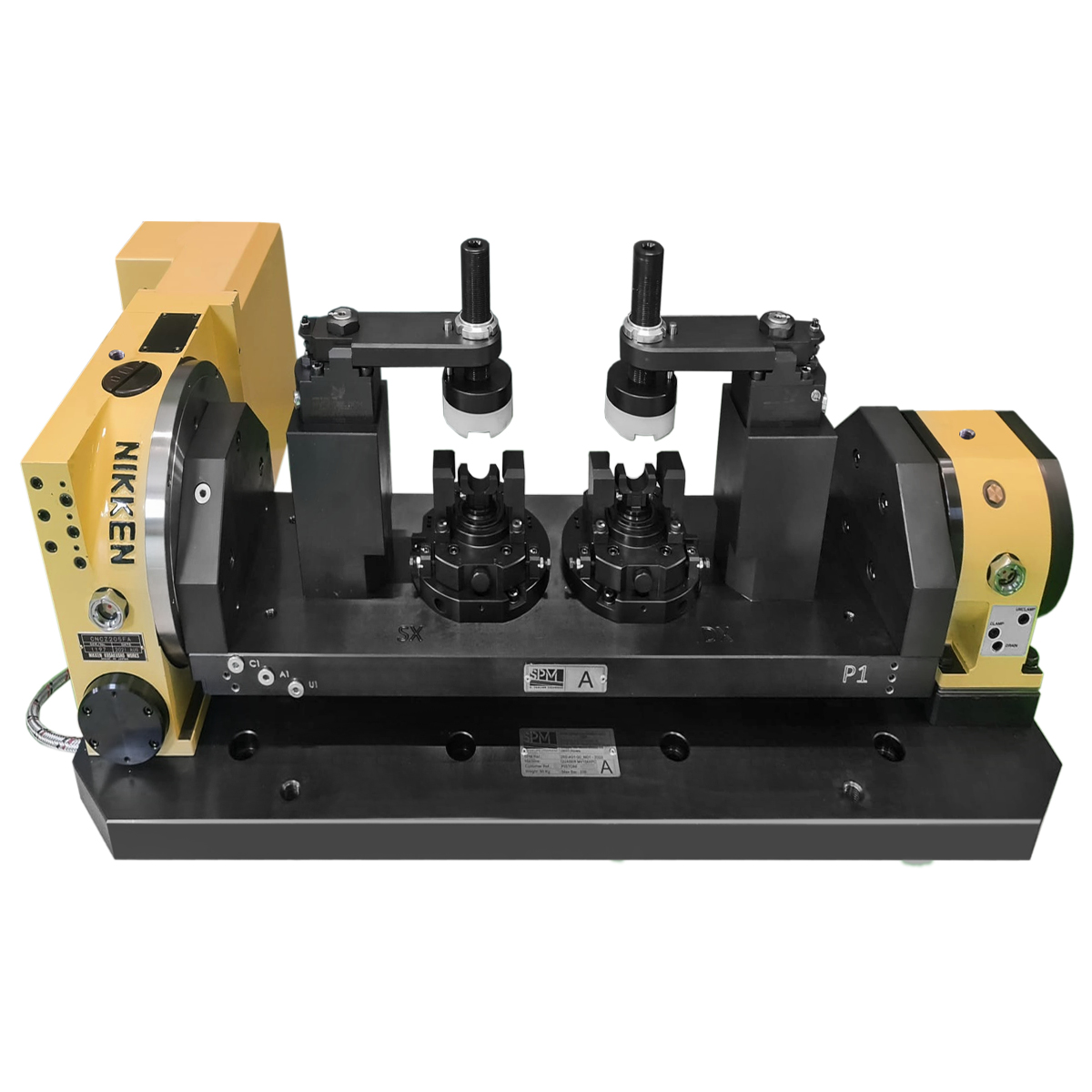

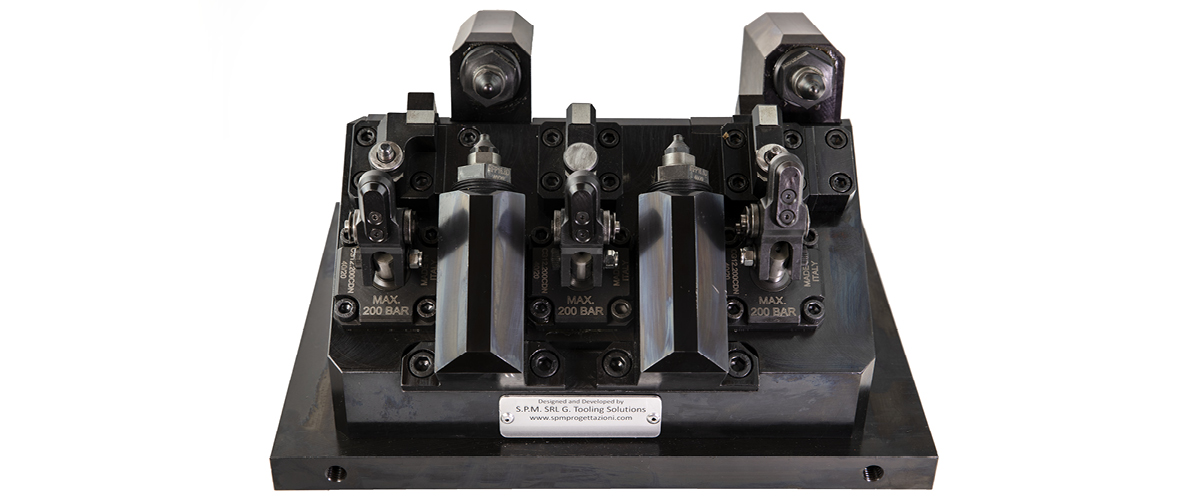

CLAMPING SYSTEMS

Thanks to the experience consolidated over the years and the use of innovative computer and design programs, S.P.M. is able to provide cutting-edge equipment for every type of detail.

The diversity of sectors in which we are present allows us to find alternative and always innovative solutions for different applications.

Knowledge of mechanical processes and materials guarantees safety for the products made.

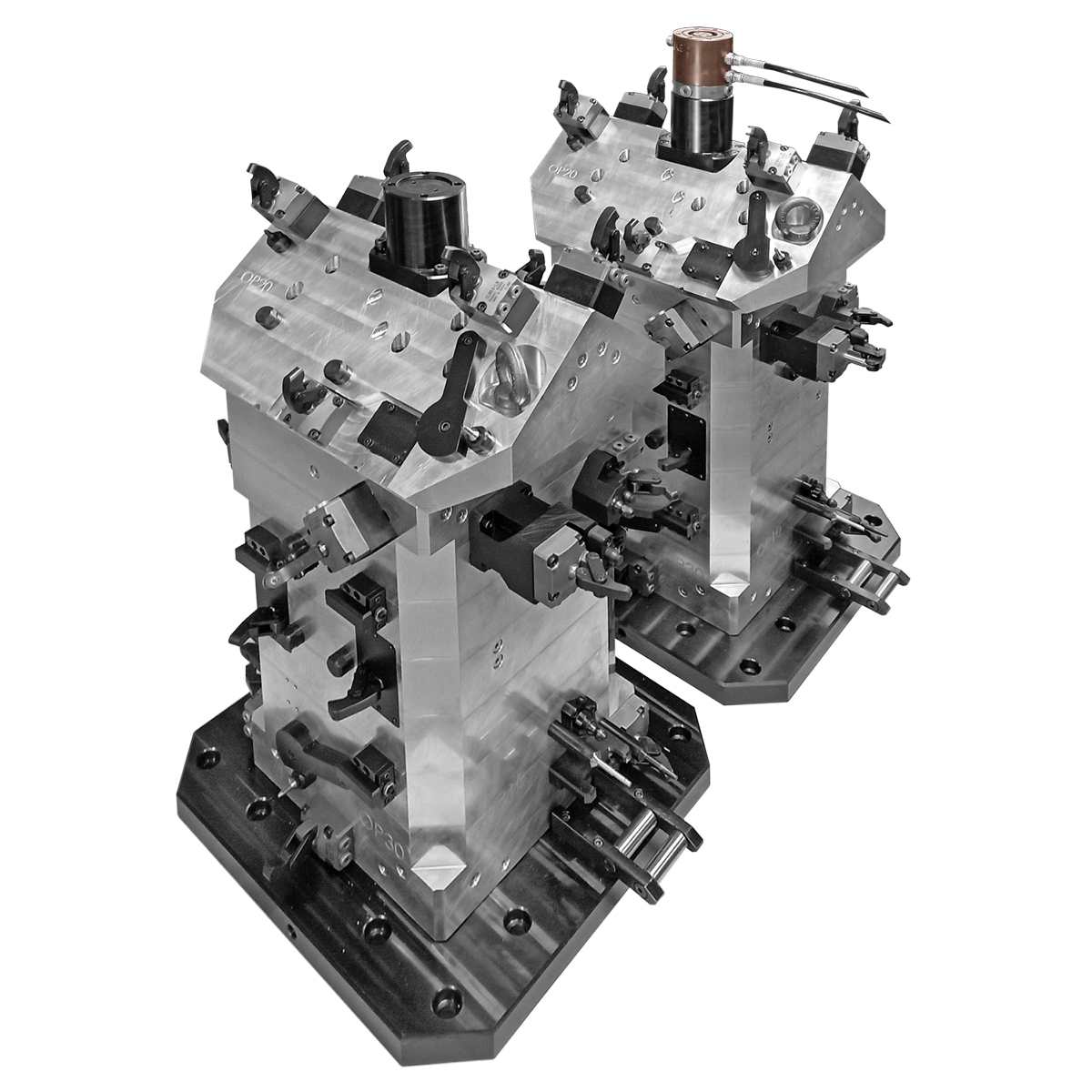

Methods and procedures implemented over the years and consolidated with ISO9001 certification in 2018 for the design and construction of equipment guarantee professionalism and fundamental steps for quality work where the Customer remains constantly updated on the progress and guarantee traceability of the project in every phase.

4 weeks

Team project’s

assignment

Design and

Development

Process control

working area

and tools passage

Customer’s

Approval

Comparison

with the Customer

to satisfy

all their needs

Management

Project

Periodic updates

work progress

6 weeks

Construction

and Testing

Dimensional testing

on 3D machine

and functional testing

hydraulic/pneumatic

Installation

Release

technical file

and user manual

and maintenance

4 weeks

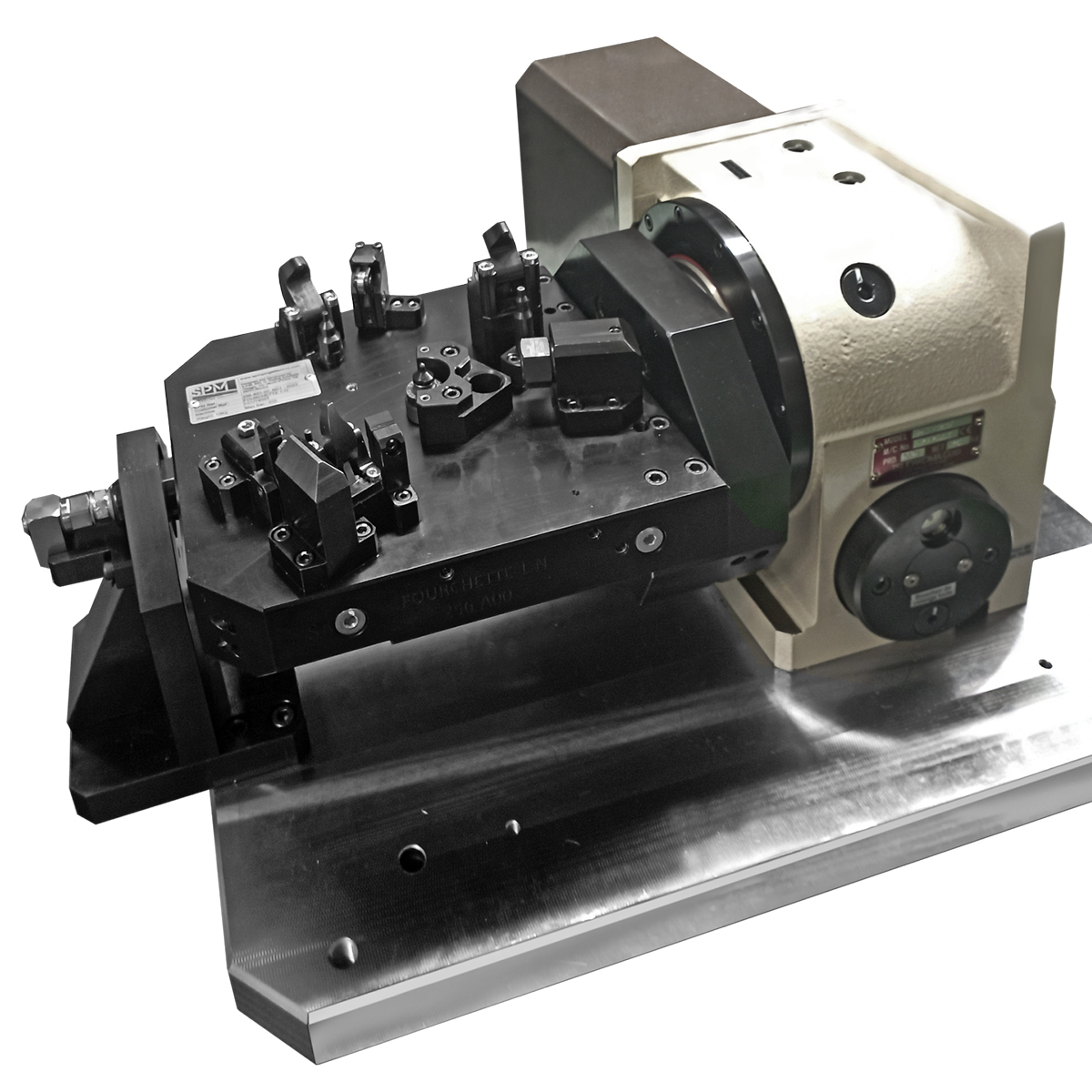

- Team project’s assignment

- Design and Development: process control working area and tools passage

- Customer’s Approval: comparison with the Customer to satisfy all their needs

- Management Project: periodic updates work progress

6 weeks

- Construction and Testing: dimensional testing on 3D machine and functional testing hydraulic/pneumatic

- Installation: release technical file and user manual and maintenance